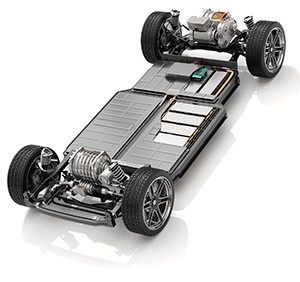

Nordfab has the high quality ducting and the experience with duct system design which is required for dust collection systems in EV battery and component manufacturing facilities.

Nordfab has the high quality ducting and the experience with duct system design which is required for dust collection systems in EV battery and component manufacturing facilities.

The Right Ducting

Nordfab’s Quick-Fit® clamp-together ducting is installed in hundreds of thousands of industrial and commercial air filtration and dust collection applications, including battery assembly plants. Quick-Fit offers these benefits:

Learn more about the benefits of Quick-Fit and QFS sealed duct

The Right Expertise

Nordfab introduced Quick-Fit clamp-together ductwork, with its unique rolled edge ends and easy-to-use clamps, in 1990. As well as being the originator, Nordfab is the industry leader, and the world’s largest manufacturer of clamp-together ducting for industrial ventilation, with capability of producing 3500 pipes per day.

The Right Resources

For facility designers and engineers, Nordfab offers:

Our capabilities include:

An expert Nordfab dealer can help you with layouts, including a 3D installation design, and exact product selection and design of custom products. Contact us to request assistance

Visit Nordfab at The Battery Show in 2025 - in Atlanta in April or Detroit in October

Nordfab ducting is installed in hundreds of thousands of manufacturing facilities, including EV battery gigafactories and automotive component manufacturing plants.

A Nordfab packer pulls Quick-Fit pipe from stock at our manufacturing facility in Thomasville, NC.

Nordfab Ducting sponsored a webinar titled Innovations in Battery Manufacturing: Comparing Dry and Wet Electrode Processing.

Viewers will gain a comprehensive understanding of how each process impacts the final battery product, operational costs, and environmental footprint. The session aims to provide insights into the current state and future directions of electrode manufacturing technologies, fostering a deeper understanding of their roles in advancing the battery industry.